Toilets play a vital role in maintaining cleanliness and hygiene in homes, offices, and public spaces. Regular inspections are essential to ensure their functionality and sanitary condition. This article aims to provide an overview of the inspection content and procedure for toilets.

During the production process of toilets, they usually undergo multiple inspections, including inspection of the embryo and finished product. In general, the national standard requirements for toilet products can be summarized into two major aspects. On the one hand, it is the requirements for the ceramic body and glaze, and on the other hand, it is the requirements for water consumption and sewage discharge effect. The detection of ceramic body and glaze requires the use of instruments under specific conditions. In comparison, the detection of toilet water consumption and sewage discharge effect is much simpler and more intuitive.

I. Content of Toilet Inspection

The manufacturer will inspect

First of all, workers will heck the toilet bowl and tank for any visible cracks or damages.Then inspect the flush mechanism for smooth operation and adequate water flow.After that, examine the seat and lid for proper attachment and any signs of wear or damage.Finally,verify that all external parts, such as handles and knobs, are in good working condition.These contents will generally be inspected in the production factory, and some special equipment and materials will be used specifically to inspect these items.

Users can check

As the user, you must check to make sure this product will fit and function well in your bathroom. You can refer to the following steps to check.

First, test the flush to verify its effectiveness in clearing waste. Second, inspect the sewer line connection to ensure it is properly sealed and not leaking. Third, check the water supply lines and valves for any signs of leakage or corrosion. Fourth, evaluate the condition of the wax ring seal between the toilet and the floor. Fifth, examine the overflow tube to ensure it is functioning correctly and preventing water overflow.

WATER LEAKING MAY CAUSE YOUR BATHROOM A MASS

II. Procedure for Toilet Inspection

In our inspection preparation, the preparation of tools is essential. Some common tools can also help us quickly detect whether the quality of the toilet is up to standard. Gather the necessary inspection tools, such as a flashlight, gloves, and a notepad.

Professional staff will start by examining the toilet bowl and tank for visible damages or cracks. Assess the condition of external components, including handles, knobs, and the flush mechanism.Take note of any issues, such as loose or broken parts, for further evaluation.

Now we can move to internal inspection. Carefully inspect the flushing mechanism, checking the water flow and effectiveness.Then examine the sewer line connection and water supply lines for any signs of leakage or damage. Evaluate the condition of the wax ring seal and the overflow tube. Document any identified problems to guide future repairs or maintenance.

Sanitary Assessment

Ensure personal safety by wearing gloves and using a flashlight to inspect the bowl’s cleanliness. Look out for any mold, mildew, or unpleasant odors that may indicate sanitation issues. Verify the presence and proper functioning of seat cover dispensers, if applicable. Assess the condition of nearby handwashing facilities to ensure proper hygiene standards.

CRACK WILL HAPPEN WHEN BOWL IS THICK AND OLD

III. More professional testing content

Inspection 1: solid emissions

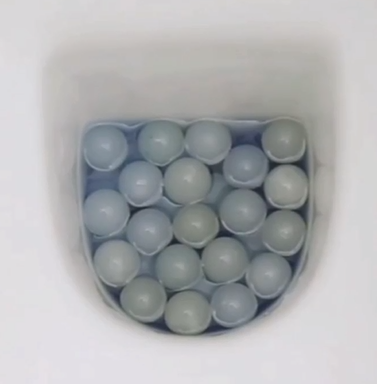

When choosing a toilet, the most important thing to consider is its sewage discharge capacity. If the excrement cannot be flushed away no matter how much it is flushed, no matter how expensive or water-saving the toilet is, it will be of no use. How to test the toilet’s sewage discharge capacity? The national standard clearly stipulates: use the small ball test and the mixed particle test as inspection methods, and judge whether the sewage discharge effect meets the standard by observing the number of flushed solids.

FLUSH TEST WITH BALLS

Inspection 2: Flush cleaning function

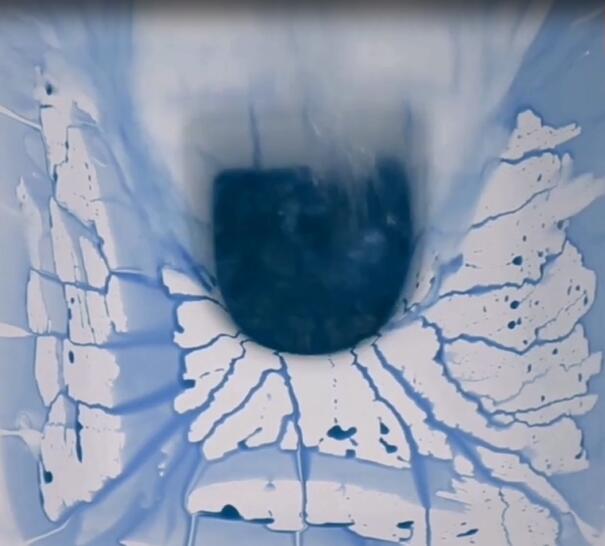

It is not enough to flush away the solid emissions in the toilet water seal. Many times, the inner wall of the toilet will be covered with stains. At this time, water power needs to be used to flush them clean. In the national standard, the cumulative length of the ink line is used to test the strength of the toilet’s cleaning ability.

FLUSH CLEANING TEST WITH INK

Inspection 3: passing ball diameter

I believe all of my friends must have had this experience: the toilet upstairs or downstairs is clogged. Not only can you not go to the toilet, it may even make you miserable. In fact, the toilet is clogged because something is stuck in the sewage pipe. If the diameter of the sewage pipe is large enough, blockage will be difficult to occur.

In this regard, the national standard uses the diameter of the toilet ball to check whether the sewage pipe is easily blocked. Generally, the diameter of the toilet sewage pipe is between 45-50mm, and it will be slightly narrower in the middle part of the pipe. If the narrowest position of the pipe can pass a solid ball with a diameter of 41mm, it will meet the requirements of the national standard ball diameter test

Although toilets are easily overlooked products in our daily lives, their testing cannot be ignored. They play a very important role in maintaining our physical health and cleaning the environment. If you want to buy a good toilet, you must choose a product that has been produced in a standardized manner. Come and take a look at our website, more professional knowledge is waiting for you to discover.