The choice between porcelain and ceramic ultimately depends on the intended use, budget, and desired appearance. Porcelain tends to offer better durability, moisture resistance, and a more refined look, making it ideal for high-traffic areas and wet environments. Ceramic, on the other hand, offers a more affordable option for dry spaces and lower-traffic areas where extreme durability is not as crucial.

If quality and longevity are the most important factors for your project, porcelain is likely the better option. However, if budget is a major consideration and the area is not subject to heavy wear or moisture, ceramic may offer a more cost-effective alternative.

Composition and Manufacturing

Porcelain is a subtype of ceramic that is made from refined clay and minerals like feldspar and kaolin. It is fired at a higher temperature than standard ceramic, usually between 2,200°F and 2,600°F. This high firing temperature results in a denser, harder, and more durable material.

Ceramic tiles, on the other hand, are typically made from a mixture of clay and other natural materials like sand and quartz. The firing temperature for ceramic tiles is lower, around 1,800°F to 2,000°F, which gives them a more porous, softer composition than porcelain.

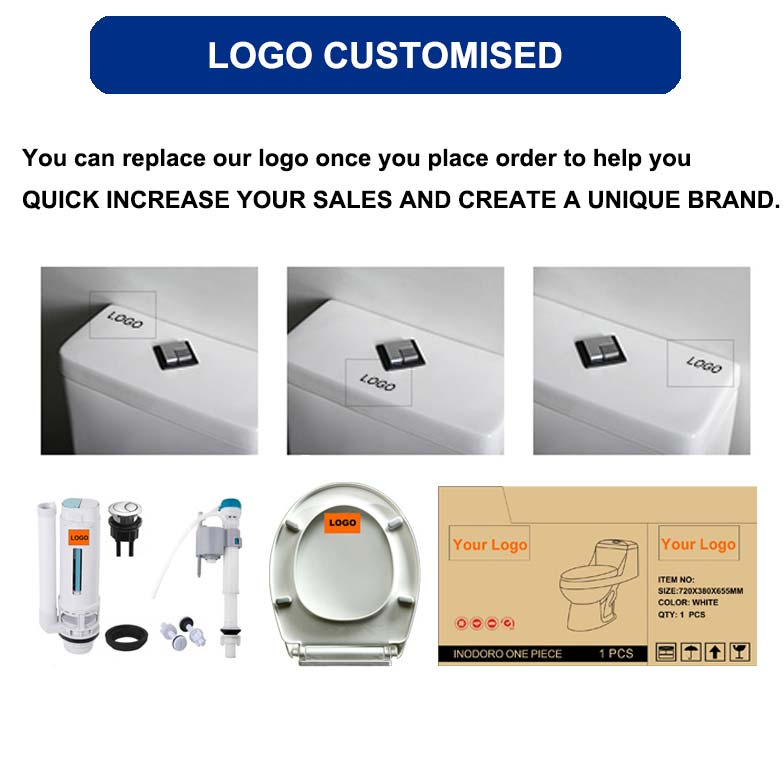

Bathroom products

Durability and Strength

Porcelain is generally considered more durable and stronger than ceramic. Due to its denser composition, porcelain is more resistant to moisture, staining, and scratching. This makes it ideal for high-traffic areas and places exposed to moisture, such as bathrooms, kitchens, and outdoor environments. Its strength also means that porcelain can handle heavy foot traffic and the weight of furniture without cracking or chipping.

Ceramic tiles, while durable, are typically not as strong or moisture-resistant as porcelain. They can absorb more water due to their more porous nature, which can lead to issues in wet areas. While they are suitable for lower-traffic spaces and dry areas, they are more prone to damage in high-moisture environments.

Aesthetic Appeal

Both porcelain and ceramic offer a wide range of aesthetic options, including various colors, textures, patterns, and finishes. However, porcelain often has a more refined, polished finish due to its denser composition. It can also be made to mimic natural materials like marble, stone, and wood with high precision. Porcelain tiles often have a uniform color throughout, which means that chips or scratches are less noticeable.

Ceramic tiles can also be made in various designs, but they often have a less polished, more rustic appearance. Ceramic tiles may also have a glazed surface, which gives them a shiny, colorful finish. However, ceramic tiles are usually more susceptible to wear on the surface, as the glaze can wear away over time.

Sanitary ware products

Cost

Generally, ceramic tiles are less expensive than porcelain. The lower firing temperature and less refined raw materials contribute to the reduced cost of ceramic tiles. Additionally, the installation of ceramic tiles can be cheaper, as they are lighter and easier to cut and handle than porcelain tiles.

Porcelain tiles, being more durable and often heavier, tend to cost more both in terms of material and installation. However, the added expense can be worth it for high-traffic or wet areas where durability is crucial.

Maintenance

Both porcelain and ceramic tiles are relatively easy to maintain, but porcelain requires less upkeep in the long run due to its lower porosity. Porcelain tiles are less likely to absorb stains or moisture, making them easier to clean. Ceramic tiles may require more frequent sealing, especially in areas with high moisture content, to prevent water absorption and staining.

Wall hung toilet

Fohome Sanitary ware Co.,Ltd is a fast growing company in researching, designing,manufacturing and sales of sanitary ware products for more than 10 years. Our main products are ceramic toilet, wash basin,bidet, urinal, bathroom cabinet,faucets etc.Our company is located in large domestic sanitary ware production base.

Changge,Henan with advanced production lines,first-class quality management as well as full service and support.

We have full production lines including R&D , automatic high press grouting lines, forming,robot glazing lines, drying(1280’c fire kiln) which ensure the annual production capacity reach 4,000,000pieces in fast delivery. Fohome focuses on quality control which covers from raw material,semi-product, finished product, fittings, package etc. Until now we have successfully help more than 30 customers from North and South America, Western and Eastern Europe, India, Middle East,Southeast Asia, South Africa explore and seize the market.

Contact Us:

Tel:+86 13937950777

Whatsapp:008613937950777

Email:annie@fohomeceramics.com