Choosing the right toilet factory is a critical decision for toilet suppliers, as it directly impacts product quality, customer satisfaction, and overall business success. In a competitive market where product differentiation and customer experience matter more than ever, suppliers must carefully evaluate several key factors before partnering with a toilet manufacturer. This article outlines the most important aspects that toilet suppliers should focus on when selecting a factory to ensure high-quality products, efficient production, and long-term success.

1. Product Quality and Standards

The most important factor in selecting a toilet factory is product quality. Toilets are essential household fixtures that need to meet high performance and durability standards. Suppliers should ensure that the factory follows strict quality control measures at every stage of production, from material selection to final assembly.

Key Quality Indicators:

- Material Quality: High-grade ceramic, porcelain, or vitreous china should be used to ensure strength and resistance to cracking.

- Flush Performance: The factory should produce toilets that offer powerful yet water-efficient flushing systems, meeting regulatory requirements such as WaterSense in the U.S.

- Surface Finish: A smooth, non-porous glaze helps prevent stains and bacterial growth, ensuring hygiene and easy cleaning.

- Structural Integrity: The toilet’s ability to withstand weight and pressure without cracking or deforming is critical.

Suppliers should request product samples and conduct independent quality tests before committing to a factory.

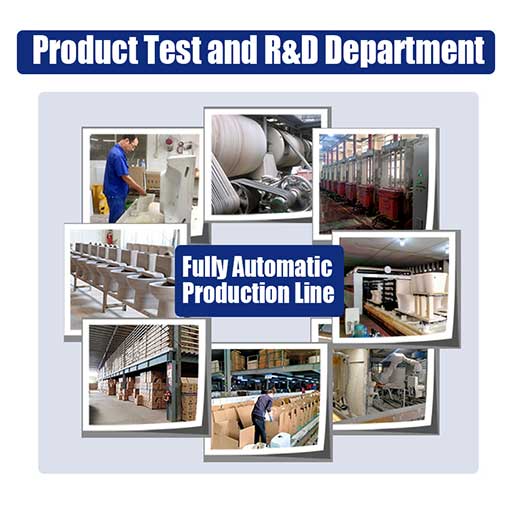

2. Manufacturing Capabilities and Capacity

The production capacity and technical capabilities of the factory are equally important. A supplier needs to assess whether the factory can meet their order volume and delivery timelines consistently.

Considerations:

- Production Volume: Can the factory handle both small and large orders without compromising quality?

- Automation and Technology: Factories using modern manufacturing technologies, such as automated kilns and robotic glazing, often deliver more consistent products.

- Flexibility: The ability to adjust production lines to accommodate design changes or urgent orders is a key advantage.

- Lead Times: Reliable lead times ensure that the supplier can fulfill customer demands without delays.

fully-automatic-production-line

3. Compliance with Industry Regulations and Standards

Toilets are subject to various health, safety, and environmental regulations. Suppliers must ensure that the factory complies with both local and international standards.

Essential Certifications:

- ISO 9001: Quality management certification ensures that the factory follows consistent production and quality control processes.

- WaterSense (U.S.): Certification for water efficiency helps suppliers meet customer demands for eco-friendly products.

- CE Marking (Europe): Compliance with European safety and performance requirements.

- Environmental Standards: Factories should follow sustainable practices, such as recycling wastewater and reducing energy consumption.

our-certificate

4. Design and Innovation Capabilities

Consumer preferences for toilet designs are constantly evolving. Suppliers should partner with factories that have strong research and development (R&D) capabilities and are willing to collaborate on new designs.

Factors to Evaluate:

- Customization: Ability to offer different shapes, colors, and flush mechanisms to meet market preferences.

- Smart Features: Factories with expertise in smart toilets (e.g., bidet functions, seat heating, automatic cleaning) give suppliers a competitive edge.

- Trend Adaptability: Factories that keep up with design trends, such as minimalist and space-saving models, help suppliers stay relevant in the market.

5. Cost Structure and Pricing Transparency

Cost is a major factor when selecting a factory, but the cheapest option is not always the best. Suppliers should seek factories that provide competitive pricing while maintaining high quality.

Pricing Considerations:

- Material Costs: Ensure the factory is using quality raw materials at a reasonable cost.

- Labor Costs: Factories in different regions will have varying labor costs, affecting the final price.

- Shipping and Tariffs: Consider additional expenses related to international shipping and import duties.

- Hidden Costs: Clarify whether tooling, mold creation, and quality inspections are included in the production price.

Suppliers should negotiate clear and transparent contracts to avoid unexpected expenses.

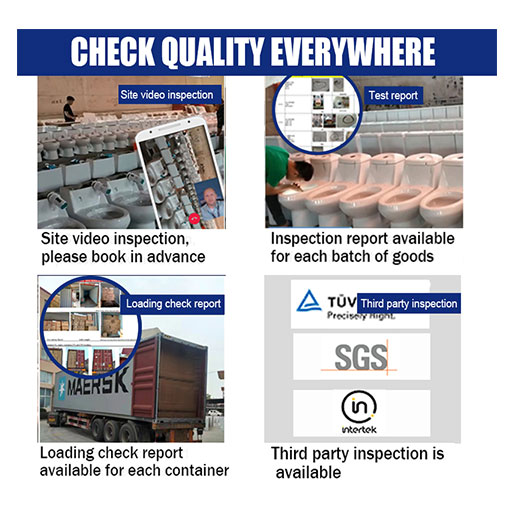

6. Reputation and Reliability

A factory’s track record speaks volumes about its reliability and professionalism. Suppliers should research the factory’s reputation through customer testimonials, third-party reviews, and industry references.

Evaluation Methods:

- Site Visits: Touring the factory allows suppliers to assess working conditions, production processes, and management practices.

- Customer Feedback: Reviews from other suppliers and partners provide insight into the factory’s consistency and reliability.

- Longevity: A factory that has been in business for many years is more likely to have stable production and experienced staff.

check-quality-everywhere

7. Ethical and Environmental Practices

Consumers are increasingly concerned about the ethical and environmental impact of their purchases. Suppliers should work with factories that follow fair labor practices and minimize environmental harm.

Important Factors:

- Fair Labor Practices: Ensure that workers are paid fair wages and work under safe conditions.

- Eco-Friendly Manufacturing: Factories that recycle materials, use energy-efficient equipment, and reduce water consumption align with sustainability goals.

- Waste Management: Proper disposal of ceramic waste and chemical residues is essential for environmental responsibility.

Conclusion

Choosing the right toilet factory is a strategic decision that affects product quality, customer satisfaction, and business profitability. Suppliers should carefully evaluate factories based on product quality, manufacturing capacity, compliance with standards, design capabilities, cost structure, reputation, and ethical practices. A thorough selection process ensures that the supplier can deliver high-quality, innovative, and competitively priced toilets, ultimately securing a strong position in the market. By prioritizing these key factors, toilet suppliers can build long-term, successful partnerships with reliable manufacturing partners.