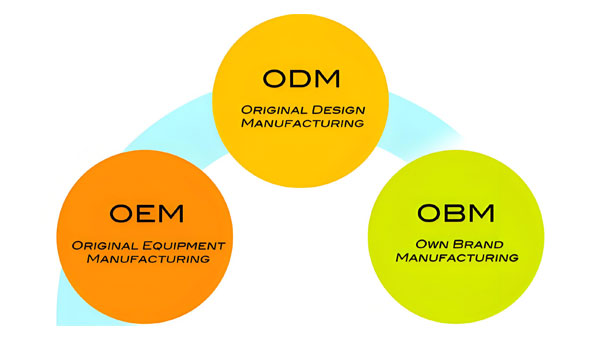

The global toilet industry, a key segment in the broader bathroom products market, has seen significant advancements in design, technology, and manufacturing processes over the years. As the demand for high-quality and cost-effective sanitary products grows, Original Equipment Manufacturing (OEM) and Original Design Manufacturing (ODM) have become essential business models for companies involved in toilet production. These models offer various advantages for both manufacturers and buyers, particularly in terms of cost-efficiency, customizability, and speed to market.

What is OEM (Original Equipment Manufacturing)?

OEM refers to the practice where a company designs and manufactures a product that is then branded and sold by another company under its name. In the context of toilets, an OEM supplier is responsible for producing toilets based on a buyer’s specifications, which can include everything from size, materials, and technology, to packaging.

A toilet OEM manufacturer typically follows strict guidelines set by the client, who usually provides the design or has a certain functional specification. OEM products are often sold under the buyer’s brand name, allowing the buying company to focus on branding, distribution, and marketing, while the manufacturer handles the production process.

What is ODM (Original Design Manufacturing)?

ODM, on the other hand, is a business model where the manufacturer not only produces the product but also designs it. In this case, the manufacturer plays an integral role in creating the design and functionality of the toilet, and then offers it to the buyer who can brand and sell the product as their own.

ODM offers a higher degree of flexibility and convenience for companies that may not have the resources or expertise to develop their own product designs. Manufacturers can provide a range of pre-designed toilet models or even modify existing designs to suit the needs of their clients. This allows businesses to bring innovative toilet products to market without investing in the extensive design and development process.

Benefits of OEM and ODM in the Toilet Industry

Both OEM and ODM models have distinct advantages for businesses in the toilet industry:

Cost-Effectiveness

For both OEM and ODM, the primary advantage is often cost savings. By outsourcing production, companies can avoid the high costs associated with setting up their own manufacturing facilities. Additionally, large-scale manufacturers can often achieve economies of scale, leading to lower per-unit production costs.

Time Efficiency

Manufacturers that already have established production lines for toilet products can produce goods more quickly than companies trying to handle every aspect of manufacturing themselves. This allows for faster time-to-market, which is crucial in the competitive bathroom product industry.

Customization

While OEM products are typically customized to the specifications of the buyer, ODM offers even more flexibility by allowing companies to work closely with manufacturers on product design. ODM can provide a unique opportunity to bring innovative, proprietary designs to market without the need for an in-house design team.

Quality Control

Working with established OEM and ODM manufacturers allows companies to benefit from their expertise in quality control. These manufacturers often have rigorous testing processes in place, ensuring that the final product meets safety standards and performs reliably over time.

Focus on Core Competencies

By relying on OEM or ODM partnerships, companies can focus on their core competencies such as marketing, distribution, and customer service, leaving the complexities of manufacturing to those with specialized knowledge and resources.

Challenges in OEM and ODM Models

While the benefits are numerous, there are also challenges that businesses should be aware of when working with OEM and ODM manufacturers:

- Quality Assurance: Ensuring that the manufacturer adheres to the quality standards set by the buyer can sometimes be difficult, especially when there is a lack of communication or oversight during production.

- Intellectual Property Risks: When collaborating with an ODM manufacturer, there is always a risk that the design may be copied or adapted for another client, which could lead to potential market competition.

- Supply Chain Disruptions: Relying on manufacturers in different regions or countries can expose businesses to supply chain risks such as delays, shipping issues, and geopolitical challenges.

- Limited Control Over Design and Production: While OEM and ODM models offer customizability, companies may still find themselves limited by the manufacturer’s capabilities or unable to make last-minute changes to the design once production begins.

Conclusion

The OEM and ODM business models have become central to the global toilet manufacturing industry, allowing companies to streamline their operations, reduce costs, and bring high-quality products to market quickly. These models offer flexibility, innovation, and cost efficiency, making them ideal for businesses seeking to meet the evolving demands of the modern consumer. However, businesses must also carefully consider the challenges associated with these models, particularly in terms of quality control, intellectual property, and supply chain risks. Ultimately, choosing between OEM and ODM depends on the specific needs, resources, and strategic goals of the company involved.