Bathroom ceramics face significantly higher damage risks compared to general goods. According to a 2023 International Fragile Goods Transportation White Paper cited in , traditional transportation methods using ordinary wooden crates or bubble wrap result in a staggering 23% damage rate. This is particularly critical for high-value items like ceramic bathtubs, where even 0.1mm cracks render products 100% scrapped . E-commerce logistics data further highlights the severity: ceramic products experience an 18% damage rate during transit, three times the e-commerce average of 8% . These figures underscore the urgent need for specialized solutions.

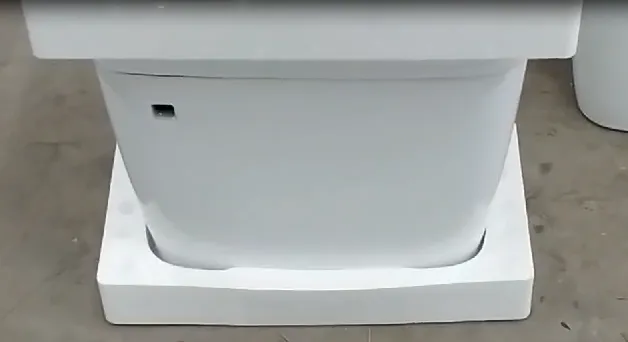

Bathroom toilet

Bathroom ceramics—such as toilets, washbasins, and ceramic tiles—are staple products in the global home improvement and construction sectors. However, their inherent brittleness, irregular shapes, and relatively large volumes make them highly susceptible to damage during international transportation. Long-haul trade involves multiple links, from warehousing and loading to sea/land shipping, transshipment, and unloading, each posing risks of collision, extrusion, or vibration-induced breakage. Damage not only causes direct losses (e.g., product costs, shipping fees, customs duties) but also leads to project delays, damaged business reputations, and even cross-border disputes. Addressing this challenge requires a comprehensive, multi-link strategy. Below, we elaborate on key solutions, with a focus on our core measures, to minimize damage risks effectively.

Carton packaging

- Packaging Optimization: The First Barrier Against Damage

Packaging is the primary line of defense for bathroom ceramics, and we prioritize this link by adopting 5-layer corrugated standard export cartons as our base packaging solution. Unlike ordinary 3-layer cartons, 5-layer corrugated cartons feature a reinforced structure: two outer liners, two inner liners, and a wave-shaped corrugated medium in between. This design delivers dual advantages: the corrugated medium absorbs and disperses impact forces during transit, while the multi-layer liners enhance load-bearing capacity, preventing crushing under stacked goods. Moreover, these cartons comply with international export standards, including resistance to moisture (critical for sea shipping) and dimensional stability, ensuring they withstand harsh conditions like temperature fluctuations and port handling.

Custom foam packaging

To meet some customer needs and further enhance protection, we also equip cartons with customized internal cushioning, such as foam packaging, which perfectly

conforms to its contours, supports each surface and avoids stress concentration.

Real-time monitoring

- On-Site Loading Supervision: Securing Goods Before Containerization

Even with robust packaging, improper loading can render protection ineffective. We therefore implement strict on-site loading supervision to ensure goods remain intact before entering containers. Our supervision team comprises professionals with deep experience in fragile goods logistics and bathroom ceramic properties, responsible for three key tasks:

First, pre-loading inspection: Supervisors check each carton for tears, deformation, or loose sealing. They also gently shake cartons to detect abnormal sounds (indicating potential internal damage) and set aside any defective packages for re-inspection or repackaging—no substandard goods are loaded.

Second, loading process guidance: Supervisors ensure the container floor is clean and dry (laying moisture-proof film if needed) and require handlers to use forklifts with soft rubber pads or manual belts to avoid rough handling (e.g., dropping, colliding). They enforce stacking rules: “heavy goods at the bottom, light goods on top; large items first, small items later” to keep the center of gravity stable. For most ceramics, stacking height is limited to 1.5 meters to prevent crushing lower cartons.

Third, gap filling: Any spaces between stacked goods and container walls are filled with airbags or foam boards to reduce collision risks caused by container shaking during transit.

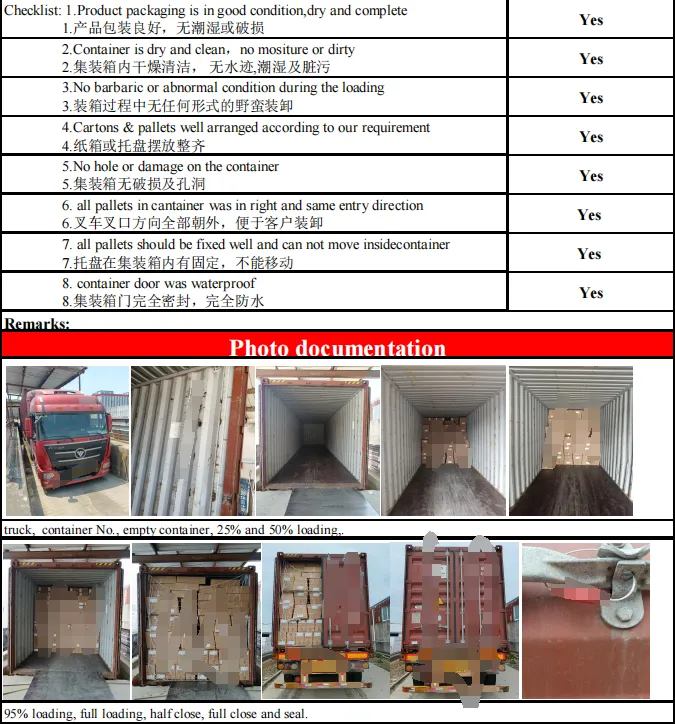

Loading check report partial content display

- Loading checkReports: Transparent, Traceable Status Updates

To keep customers informed and enable accountability, we issue a detailed loading check report after each operation and send it to customers within 24 hours. This report is both a transparency tool and a legal safeguard, containing:

Basic information: Shipment date, container number, product batch, and a breakdown of quantities (e.g., 50 units of Toilet Model X, 30 units of Washbasin Model Y).

Packaging status: Photos of 5-layer cartons, internal cushioning, and sealing, verifying compliance with standards.

Inspection results: Number of qualified/unqualified goods, reasons for defects (if any), and corrective actions (e.g., repackaging, replacement).

Customers use this report to confirm goods status in real time. In case of post-transit damage, the report serves as critical evidence: if goods were intact at loading, we work with logistics and insurance providers to resolve claims; if pre-loading issues exist, we address them proactively to avoid further losses.

- Supplementary Measures: Building a Comprehensive Protection System

The three core measures above are reinforced by additional strategies to form a full-chain protection network:

Selecting reputable logistics partners: We assess logistics companies based on their fragile goods safety records, vehicle/ship conditions, and emergency response capabilities. During transit, We track the goods in time and maintain close communication to resolve delays or route changes promptly.We also provide a receiving guide, reminding customers to inspect goods immediately upon arrival and report damage promptly.

container

Preventing bathroom ceramic damage in international transportation demands a systematic, multi-link approach—not isolated measures. Our 5-layer corrugated cartons and customized cushioning form a solid first defense; on-site supervision eliminates pre-containerization risks; loading reports ensure transparency; and supplementary steps strengthen overall safety. By integrating these strategies, we minimize losses, ensure smooth trade, and build long-term customer trust. Going forward, we will continue optimizing these measures based on customer feedback and global logistics trends, further enhancing damage prevention for bathroom ceramics and achieve higher customer satisfaction.

At Fohome sanitary ware,We can provide you with toilets, pedestal basins, bidets, etc. We export to many countries around the world.We specialized in sanitary ware for 15 years,with the 3 tunnel kilns with annual supply capacity of 2,500,000pcs and quality control system covering raw material/semi and finished product/packing etc.

We welcome more partners to join us, if you are a buyer, wholesaler or agent,Welcome to contact now, OEM and ODM service are availbale.